- Home Page

- Company Profile

-

Our Products

- VK System

- Cross Core

- Homogenizer

- Bottom Homogenizer

- Contra Mixer

- Cone Mill

- Centrifugal Sifter

- Chemical Reactor

- Food Mixer Machine

- Emulsion Plant

- Food Processing Machine

- Mayonnaise Processing Machine

- RUTF/RUSF Plant

- Hummus Plant

- Mayonnaise Making Plant

- Mayonnaise Processing Machine

- Food Making Machine

- Ribbon Blender

- Amla Boiling Machine

- Tray Dryers

- Wet Pulverizer

- Dry Fruit Processing Machine

- Fruits And Vegetable Washer

- Peanut Paste Making Machine

- Ginger Garlic Paste Making Machine

- Canning Retort

- Marzipan Making Machine

- Coconut Cream Making Machine

- Wet Pulverizer

- Peanut Butter Plant

- Peanut Paste Making Machine

- Ginger Garlic Paste Making Machine

- Amla Boiling Machine

- Mayonnaise Making Plant

- Mayonnaise Processing Machine

- VK System

- Fruits and Vegetable Washer

- Coconut Cream Making Machine

- Ribbon Blender

- Tray Dryers

- Marzipan Making Machine

- Tower Accessories

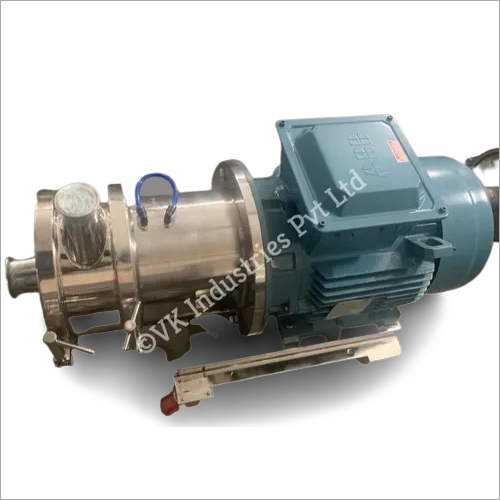

- Inline Mixer Or Homogeniser

- Bead Mill Homogenizer

- Syrup In-line Mixer-Homogeniser

- Cough Mixtures In-Line Mixer-Homogeniser

- Pharmaceutical Creams In-Line Mixer-Homogeniser

- Toothpaste In-Line Mixer-Homogeniser

- Shampoo In-Line Mixer-Homogeniser

- Nail Polish In-Line Mixer-Homogeniser

- Lotion In-Line Mixer-Homogeniser

- Cream In-Line Mixer-Homogeniser

- Ointment In-Line Mixer-Homogeniser

- Rubber Solution In-Line Mixer-Homogeniser

- Polish In-Line Mixer-Homogeniser

- Automotive Polish In-Line Mixer-Homogeniser

- Paper Coating In-Line Mixer-Homogeniser

- Printer Ink In-Line Mixer-Homogeniser

- Paint In-Line Mixer-Homogeniser

- Lube Oil In-Line Mixer-Homogeniser

- Vegetable Oil Refining In-Line Mixer-Homogeniser

- Pesticide In-Liner Mixer-Homogeniser

- Edible Oil Refining In-Line Mixer-Homogeniser

- Gaur Gum In-Line Mixer-Homogeniser

- Xanthan Gum Hydration In-Line Mixer-Homogeniser

- Starch Dispersion In-Line Mixer-Homogeniser

- Jelly Or Jam In-Line Mixer-Homogeniser

- Mayonnaise In-Line Mixer-Homogeniser

- Salad Dressing In-Line Mixer-Homogeniser

- Mustard In-Line Mixer-Homogeniser

- Tomato Ketchup And Sauce In-Line Mixer-Homogeniser

- Syrup In-line Mixer Homogeniser

- Cough Mixtures in-line Mixer Homogeniser

- Pharmaceutical Creams In-line Mixer Homogeniser

- Shampoo In-line Mixer Homogeniser

- Nail Polish In-line Mixer Homogeniser

- Lotion In-line Mixer Homogeniser

- Cream In-line Mixer Homogeniser

- Ointment In-line Mixer Homogeniser

- Rubber In-line Mixer Homogeniser

- Polish In-line Mixer Homogeniser

- Automotive Polish In-line Mixer Homogeniser

- Paper Coating In-line Mixer Homogeniser

- Printer Ink In-line Mixer Homogeniser

- Paint In-line Mixer Homogeniser

- Lube Oil In-line Mixer Homogeniser

- Vegetable Oil In-line Mixer Homogeniser

- Pesticide In-line Mixer Homogeniser

- Edible Oil In-line Mixer Homogeniser

- Gaur Gum In-line Mixer Homogeniser

- Xanthan Gum In-line Mixer Homogeniser

- Jelly or Jam In-line Mixer Homogeniser

- Mayonnaise In-line Mixer Homogeniser

- Salad Dressing In-line Mixer Homogeniser

- Mustard In-line Mixer Homogeniser

- Tomato Ketchup and Sauce In-line Mixer Homogeniser

- Toothpaste In-line Mixer Homogeniser

- Starch Dispersion In-line Mixer Homogeniser

- Chemical Industry

- Colour Paint Mixing Plant

- Printer Ink Manufacturing Plant

- Motor And Engine Oil Blending Plant

- Automotive Lubricants Blending Plant

- Fertilizers Processing Tanks

- Paint Manufacturing Plant

- Lube Oil Blending Plant

- Pesticide Processing Tanks

- Automotive Lubricants Blending Plant

- Fertilizers Processing Tanks

- Motor and Engine Oil Blending Plant

- Paint Manufacturing Plant

- Lube Oil Blending Plant

- Pesticide Processing Tanks

- Colour Paint Mixing Plant

- Pharma Or Cosmetic Industry

- Liquid Oral Manufacturing Plant

- Liquid Syrup Making Machine

- Shampoo Mixer

- Shampoo Manufacturing Plant

- Shampoo Processing Vessel

- Shampoo Processing Plant

- Nail Polish Manufacturing Machine

- Ointment And Cream Processing Plant

- Liquid Oral Manufacturing Plant

- Liquid Syrup Making Machine

- Shampoo Processing Vessel

- Shampoo Mixer

- Shampoo Processing Plant

- Nail Polish Manufacturing Machine

- Shampoo Manufacturing Plant

- Particle Size Reduction Machine

- Ointment Manufacturing Plant

- Disintegrator Machine

- Vegetable And Fruit Pulping Machine

- Process Tanks Or Chemical Reactors

- Pharmaceutical Industry

- Multi Shear Mill

- Purees Making Plant

- Cosmetic Industry

- Melting Tank

- Pigment Making Machine

- Pre Engineered Building Structure

- Cable Tray

- Ointment And Cream Machines

- Dry Fruit Processing machine

- Sole Cleaner Machine

- Printer Ink Manufacturing Plant

- Cross Core

- Piston Filling Machine

- Stainless Steel Trolley

- Batch Mixer

- ss reactor

- Contact Us

Showroom

The Chemical reactors are accessible with an enclosed volume and allow for useful chemical reaction. The said units are demanded widely in chemical engineering. They are highly useful to carry out the chemical reaction and provide good utility in the analysis of chemical process.

Food Mixer Machine uses a rotor, rotating at high speeds, to direct material outwards towards a stationary stator and thus shear the material. This machine speeds provide the ability to uniquely tailor the amount of shear energy for each application. This machine is very effective as well as economical too.

Food Processing Machine is employed to produce food and food product applications ranging from bakery goods to beverages and dairy. This machine refers to the activities which convert raw food materials to final consumable products. This machine is available to execute the various unit operations necessary during a complete production cycle.

Inline mixers or homogenizers are functional as the fast as well as efficient solutions, which are capable of making a fine droplet of assorted particle size. They are required for making the creams, balms, lotions, pastes and flavor suspensions.

Chemical Industry Plants we offer are offered with stout make, superb functionality, low level of noise and extended durability. Plus, they are appreciable or their durable and innovative make.

The machines of Pharma or Cosmetic Industry are the industrial processing machines of dissimilar types. They allow for advanced level of utility and proffer a manageable operation. These machines are highly demanded for bulk drug and pharmaceuticals.

Particle size reduction machines are made to perform well with their critical stage in well-developed solids processing systems. They are accessible with an innovative method and provide advanced utility in variety of operations. These enable a consistent mixing and are appreciable for their unparalleled size reduction technologies.

Ointment manufacturing plants we offer are apt for several advanced processes. These are apt for the manufacturing of creams, lotions and several other fluid formulations. These innovative modern machines have an advanced manufacturing process and have less functional cost.

Disintegrator Machines are appreciable for their crushing methods. These reduce the materials to an appropriate mesh range. They are highly helpful for processing and grinding operation of grain as well as spice. These can convert the coarse materials into fine granules.